Advance Welding is very pleased to announce that we are an approved special process supplier for Northrup Grumman Marine Systems. Our Supplier and Quality System has met or exceeded Northrup Grumman’s requirements.

Advance Welding Named Special Process Supplier for Corp.- Marine Systems

Topics: NAVSEA

We're excited to announce the acquisition of the KTI, Inc. Electron Beam Welding and Laser Beam Welding Business Units.

Topics: News & Events

[Success Story] Electron Beam Welding for the Aerospace Industry

When an FAA customer asked us to repair a bearing seal support with only two days' notice, we welcomed the opportunity to prove its dedication to satisfying their expectations.

Topics: Electron Beam Welding, Success Stories

Electron Beam Welding for the Aerospace & Aviation Industry

A client of ours in the Aerospace/Aviation industry recently contracted us to provide electron beam welding, heat treatment, and inspection services for the radial drive shaft assembly highlighted here. We are certified to G.E. P8TF1 CL-A requirements and are uniquely capable of completing this project with a high level of integrity.

Topics: Electron Beam Welding, Success Stories

Laser and Electron Beam Welding Solutions for the Commercial Sector

When a Mississippi manufacturing client asked us to produce 30,000 assemblies for an air conditioning application, our team of designers and welders set right to the task of helping out.

The assembly process consisted of laser welding and electron beam welding.

Topics: Electron Beam Welding, Success Stories, Laser Welding

Demonstrating our expertise in using cutting-edge technologies to their full potential, we produced the double spring assembly highlighted here for a client in the automotive industry.

Topics: Electron Beam Welding, Success Stories

The distance tube assembly pictured here is one example of the many projects we do for clients in the ground-based turbine and power generation industry. Our many industry certifications, metallurgic expertise, and electron beam welding capabilities allow us to create precise welds with minimal distortion and stress on the workpiece.

Topics: Electron Beam Welding, Success Stories

Electron Beam Welding of Stainless Steel Vacuum Chamber Part

A Virginia nuclear physics laboratory asked us to improve the quality of welds in vacuum chambers used in its’ research equipment. The client was seeking a way to minimize excess heat input, distortion, and variation in magnetic properties that result from conventional fusion welding.

Topics: Electron Beam Welding, Success Stories

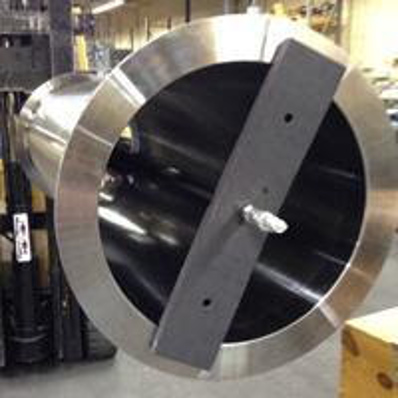

Electron Beam Welding of Steel Diaphragm for the Oil and Gas Industry

An oil and gas client in New York commonly asks us to apply our electron beam welding capabilities to steam turbine diaphragms.

Following customer specifications, the part, shown photographed below, was electron beam welded using a custom rotary fixture. The part consisted of low carbon/stainless steel materials and had an ultimate height of 4.5" and an outside diameter of 73". The welding requirements included a weld penetration depth of .900" (partial) from each side, at diameters of 44" and 67".

Topics: Electron Beam Welding, Success Stories

Advance Welding Named Approved Supplier for Gulfstream

Advance Welding is very pleased to announce that we are an approved supplier and FAA/EASA Repair Station for Gulfstream-A General Dynamics Company. Our Supplier and Quality System has met or exceeded Gulfstream Aerospace’s requirements.

Topics: Advance Welding News

![[Success Story] Electron Beam Welding for the Aerospace Industry](https://blog.theperfectweld.com/hubfs/Blog%20Images/Aerospace%20Electron%20Beam%20Welding.png)