At Advance Welding, quality isn’t a department—it’s our culture. On National Quality Day, we’re proud to highlight the systems, culture, and people that work on your parts, your timelines, and your reputation.

Celebrating National Quality Day: How Advance Welding Delivers “The Perfect Weld”

Topics: News & Events

Proud to Connect Students with Hands-On Learning Opportunities

From the day our company began more than 45 years ago, giving back to the community has been a significant part of who we are.

Topics: News & Events

Re-accreditation by Collins Aerospace Highlights Our Ability to Work with a Wide Range of Customers

Topics: News & Events

For the past 18 years, we have been part of Nadcap and are proud to have just extended our certification for another two years, through 2026. This development underscores our qualifications to provide welding, brazing, and related services to manufacturers of assemblies, parts, and components used in aerospace, aviation, and military applications.

Topics: News & Events

Developing the Next Generation of Welding Professionals

It gives us tremendous pride that Christopher Kielb, our president, was recently elected to the Board of Trustees at Western New England University (WNE) in our hometown of Springfield, MA, and will also serve on WNE’s College of Engineering Advisory Board.

Topics: News & Events

Manufacturing Process Selection Guide Vol. 2 - Laser Beam Welding

Laser Beam Welding (LBW) is an advanced technique that uses a narrow beam of light to join pieces of metal. Laser welding is used to fuse parts by forming a pool of liquefied metal at the junction point where two pieces of metal meet. This technique is better than most for joining dissimilar metals and those that are typically difficult to weld.

Topics: Aerospace Welding, Laser Welding

Reshoring, sometimes called onshoring, the process of relocating manufacturing or production operations from offshore sites to a company’s home country, began about a decade ago and accelerated during the COVID-19 pandemic. Post-pandemic, it remains a sound business strategy for six key reasons: 1) Enhanced Quality Control; 2) Supply Chain Resilience; 3) Intellectual Property Protection; 4) Greater Cost Effectiveness; 5) Sustainability and Corporate Responsibility; and 6) Improved Collaboration and Innovation.

Topics: News & Events

Our commitment to achieving The Perfect Weld every time for customers like you in the Aerospace, Defense, Energy, Medical, Semiconductor, and Automotive industries is demonstrated by the nearly 30 certifications we hold and our compliance, or self-verified conformance, with numerous standards. Our certifications include ones issued by AWS, AMS, ASME, FAA, Nadcap, EASA, SAE, and ISO – an alphabet soup of accreditation bodies. We are also ITAR-registered and compliant with CMMC (Cybersecurity Maturity Model Certification)

Topics: News & Events

Manufacturing Process Selection Guide Vol. 1 - Electron Beam Welding

Why select Electron Beam Welding (EBW)?

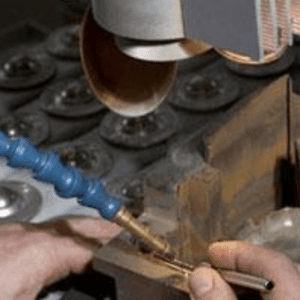

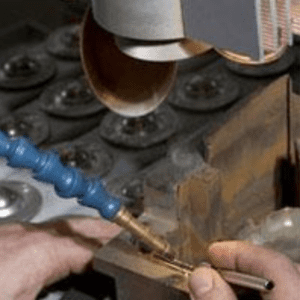

Advance Welding offers a wide range of manufacturing processes for design engineers and supply chain managers to select from, including EBW. Our team of seasoned professionals is here to help you weigh the benefits and tradeoffs of EBW as compared to other processes that we offer such as Gas Tungsten Arc Welding (GTAW/TIG), laser beam welding (LBW) and others. A key characteristic of EBW is high energy density: the minimum volume of metal is melted with the minimum heat input for a given depth of penetration. Another important characteristic is that EBW occurs under vacuum within a chamber.

EB Welded Aerospace Component

Topics: Electron Beam Welding

In this year of our 45th anniversary, now is an ideal time to reflect on how commitment to continuous improvement, teamwork, and partnerships with customers like you have allowed us to reach this milestone.

Topics: Advance Welding News, News & Events, Success Stories

-RT.jpg)

%20Welding%20audit%20%23%20223407.jpg)