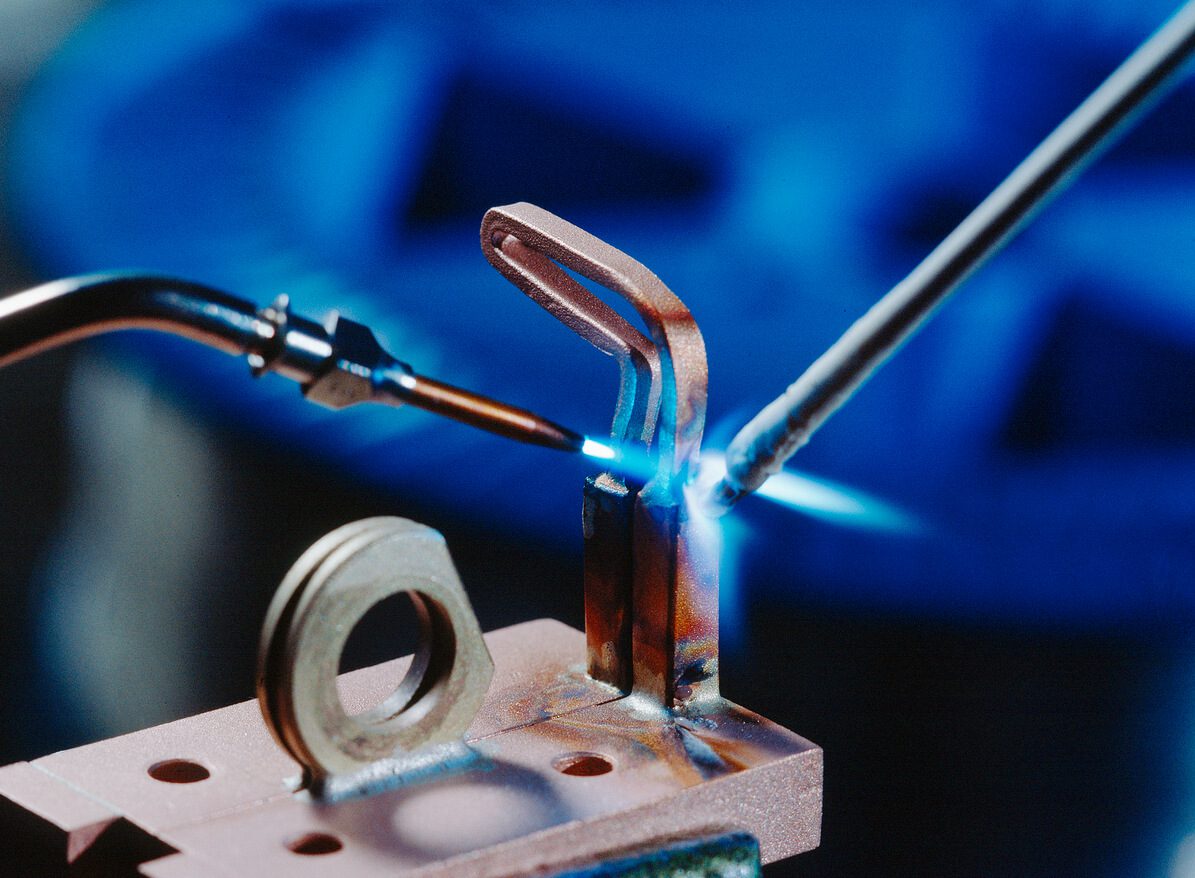

Our commitment to achieving The Perfect Weld every time for customers like you in the Aerospace, Defense, Energy, Medical, Semiconductor, and Automotive industries is demonstrated by the nearly 30 certifications we hold and our compliance, or self-verified conformance, with numerous standards. Our certifications include ones issued by AWS, AMS, ASME, FAA, Nadcap, EASA, SAE, and ISO – an alphabet soup of accreditation bodies. We are also ITAR-registered and compliant with CMMC (Cybersecurity Maturity Model Certification)

Level 2. Our dedication to cybersecurity tracks perfectly with our unwavering desire to provide the highest level of quality in everything we do for our customers and in working with our suppliers.

Our compliance with CMMC and forthcoming certification has special significance for our customers in the Defense sector because it requires us to document our cyber-hygiene practices for handling controlled unclassified information (CUI) as a subcontractor for dozens of DoD prime contractors. It also signals that we are compliant with the NIST SP 800-171 Standard which is part of the National Institute of Standards and Technology’s (NIST’s) Cybersecurity Framework. That set of suggested best practices provides guidelines for safeguarding sensitive information on federal contractors' IT systems and networks.

We have incorporated the NIST SP 800-171 Standard into our operations voluntarily because NIST, which is part of the U.S. Department of Commerce, has no auditing power or certification authority. If it did, we would gladly welcome them into our facility, just as we have had representatives from many accreditation bodies observe and evaluate our operations.

The NIST SP 800-171 standard pertains to more than 100 requirements, including Access Control, Awareness & Training, Audit & Accountability, Configuration Management, Identification & Authentication, Security Assessments, System & Communications Protection, and System & Information Integrity.

We adhere to cybersecurity best-practices guidelines related to those aspects of our business for two reasons: 1) To give you peace-of-mind that your information, including intellectual property (IP), is secure with us; and 2) We believe it is our patriotic duty to help ensure that the federal supply chain remains strong and that our national security is not compromised because of data breaches.

Upcoming: Earning & Retaining CMMC Level 2 Certification

To earn CMMC Level 2 Certification, we will provide a DoD-accredited certifying body with detailed documentation, including a System Security Plan, Risk Management Strategy, Security Control Catalog, Operational Security Procedures, Security Assessments and Authorizations, and IT Security Policies. The application process requires an exceptional amount of coordination among our team members and some after-hours work, but the “pain” will be well worth the gain for our customers and for us.

Specifically, it will formally assure customers that we have taken the most effective actions to protect information they have entrusted to us and will officially recognize that our entire team operates within guidelines designed to keep information safe.

To ensure that we remain compliant with CMMC Level 2, as well as earn and keep our future certification and remain compliant with the NIST SP 800-171 Standard, we will continue to monitor our cybersecurity and physical security practices and refine them as appropriate. Just as we are always ready to adopt the latest technologies and business practices if they help us operate more efficiently on the shop floor, we do likewise when it comes to security.

At Advance Welding, we are committed to continually investing significant resources in cyber security and physical security alike because doing so is necessary to protect the interests of our customers, especially those in the Defense sector. It is also necessary for protecting our substantial investments in production equipment and systems that help us meet your most demanding specifications.

Regardless of whether your application requires Fusion Welding, including Manual Gas Tungsten Arc, Robotic, Orbital, Electron Beam, Laser Beam; Induction & Torch Brazing, or any of our other fabrication and heat-treating capabilities, our compliance with CMMC Level 2 Certification and forthcoming certification, as well as our compliance with the NIST SP 800-171 Standard, means that your data, along with the parts and assemblies we manufacture for you, are in safe hands.

To benefit from the best practices we follow in all aspects of our operations, Contact Us