Advance Welding Nadcap, Aerospace and Mil-Spec Heat Treating Services

Heat treatment is a category of processes performed on metals to alter their physical or chemical properties by exposing them to high temperatures in order to remove impurities in the base material or alter characteristics such as toughness, strength, ductility, and hardness. Here at Advance Welding, we use heat treatment in order to remove stress from welded assemblies in order to minimize the risk of dimensional changes during post-weld machining as well as ensuring the part does not fail prematurely due to stress added from welding. In addition to Stress Relieving, we are also capable of performing both Normalizing and Age Hardening (aka Precipitation Hardening).

About Our Heat Treating Services

Advance Welding has performed these types of Heat Treating on parts for Pratt & Whitney (Tooling Services/Support Equipment), Triumph (Casting Repairs) and on parts for our FAA Repair Station customers. Stress Relieving is included in our Nadcap accreditation as a Supplement under Fusion Welding. Industries requiring these types of Heat Treating include aerospace, military/defense, power generation, and support equipment to name a few.

The purpose of stress-relieving is to remove internal forces which can be caused by hot rolling, coldworking, grinding, and welding the base material. These internal stresses can cause premature fatigue failure, ruptures, creep, and cracking. In order to prevent these metallurgic failures, we provide stress-relieving via the use of our two ovens and two furnaces.

Advance Welding also has the capability to perform various forms of Normalizing. Normalizing is a process in which a material is heated to an elevated temperature usually between 1300℉ and 1800℉. The metal is then allowed to sit at this elevated temperature for a short period of time then it is allowed to air cool. Normalizing causes the grain structure of the material to change and it develops a uniform structure which in turn provides a tougher and more ductile material.

Advance Welding is also capable of performing age hardening of most materials. Age hardening is performed by applying low heat to a material for an extended period of time. Age hardening results in an increase in yield strength.

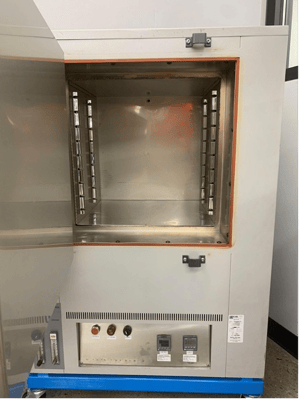

Below are Advance Welding's Heat Treatment Equipment used for Nadcap, Aerospace, Airplane Ground Support Equipment, Mil-Spec/Military/Defense, NAVSEA, and Power Generation projects that include heat treating in addition to fabrication:

Heat Treating Furnace AW1

Manufacturer: L&L Special Furnace

Internal Max Dimensions: 25” Width x 36” Height x 49” Depth

Certified Minimum and Maximum Temperature: 600℉, 1200℉

Maximum Temperature: 1875℉

Calibration: Calibrated per AMS2750

Also, Furnace AW1 is capable of functioning using an argon atmosphere.

Argon is an inert gas; inert gases are defined by their stability and non-reactivity. Due to the immense amounts of heat typically used during heat treatment processes, oxidation occurs at an accelerated rate and can leave parts covered in an oxide film, and in more extreme cases thick oxide scales form on the part. A process known as decarbonization can take place when oxygen is present during heat treatment, decarbonization can occur once a material containing iron passes 1200℉, oxygen in the atmosphere begins to bond with the carbon in the material forming carbon dioxide. This, in turn, removes carbon from the material being heat treated. This loss of carbon causes the material to soften on the surface level which gives the material uneven physical characteristics which can cause failure. By using an argon atmosphere during the heat treatment process, you minimize the amount of oxygen present during the heat treatment process. This, in turn, reduces the risk of oxidation and decarbonization from occurring.

Heat Treating Furnace AW2

Manufacturer: L&L Special Furnace

Internal Max Dimensions: 26” Width x 21” Height x 36” Depth

Minimum and Maximum Temperature: 600℉, 1200℉

Calibration: Calibrated per AMS2750

Heat Treating Oven AW2:

Manufacturer: Blue M

Internal Maximum Dimensions: 36” Width x 49” Height x 24” Depth

Certified Maximum Temperature: 300℉

Maximum Temperature: 600℉

Calibration: Calibrated per AMS2750

Despatch Electric Oven:

Manufacturer: Despatch

Internal Maximum Dimensions: 18” Width x 20” Height x 17.5” Depth

Maximum Temperature: 650℉

Calibration: Calibrated per AMS2750

Blue M Electric Heat Treatment Oven:

Manufacturer: Blue M

Internal Maximum Dimensions: 16” Width x 16” Height x 12.5” Depth

Certified Maximum Temperature: 400℉

Maximum Temperature: 1000℉

Calibration: Calibrated per AMS2750